S and S Machine

Bicycle Torque Couplings (BTCs)

Your Travel Bike........Your Only Bike!

Bicycle Torque Coupling Deflection Test

These tests demonstrate that in torsion, tension and bending, a tube

that has an S and S Bicycle Torque Coupling installed will be stiffer than

a plain section of Reynolds 531 bicycle tube. The details of how the fixtures

work are included. For a quick review of the results, see the photos with

the purple dots. The dots show how much flexing takes place. In each test

there is more flex in the plain tube than in the tube section with the

coupling. The results and conclusions for each demonstration are also included.

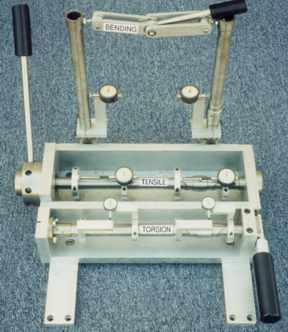

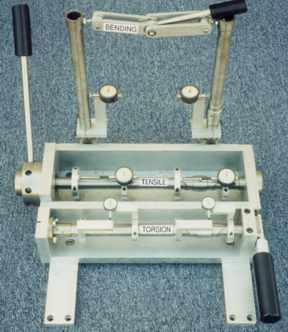

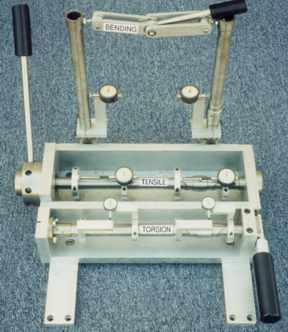

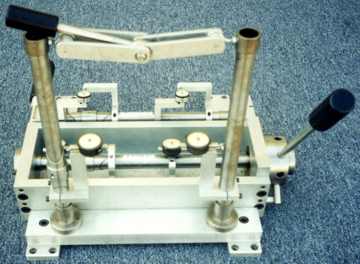

Combination torsion, tension and bending test fixture.

Front view

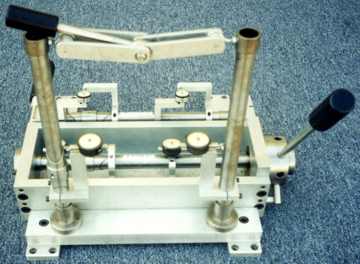

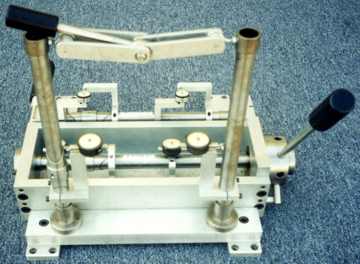

Back view

The combination test fixture

- This fixture is actually three independent test fixtures mounted on

one base for compactness. We originally made it as three fixtures but later

combined them as our booth space at bikes shows became limited.

- Only one test is performed at a time.

Standard test criteria

- Each test compares a 4 inch section of Reynolds 531 tube to a 4 inch

section of Reynolds 531 with an S and S Bicycle Torque Coupling

installed.

- In each fixture a single load is applied to both test sections simultaneously

so that the force is equal in both samples being compared.

- In each test the coupling was tightened with our standard 6" spanner

wrench.

- Flex is measured with dial indicators. The purple dots represent the

amount of indicator movement in thousandths of an inch.

Torsion test fixture

Tube only Tube with coupling

Tube only Tube with coupling

Torsion test

- Fixture layout: The fixture has a tube that is bolted in solid

on the left end and is free to rotate in a bearing on the right. A lever

is attached to the end of the tube beyond the bearing.

- Application of load: When the lever is pushed down it twists

the tube.

- Measurement method: A collar with an arm is attached to the

tube and a dial indicator is attached to the arm. A second collar with

an arm is attached 4 inches away. The indicator plunger from the first

arm rests against the second arm. Two indicator assemblies are attached

to the tube. One is placed in the plain section of tube and the other is

placed in the coupled section of tube with a collar on each side of the

coupling. When the lever is pushed down the arms on the collars move closer

together. The indicator shows the amount of twist between the arms. A stiffer

section will allow less twist.

- Results: There was.020" twist in the tube section without

the coupling. There was .009" twist in the section with the coupling.

- Conclusion: This test demonstrates that in torsion the tube

section with the coupling is stiffer than the plain tube.

Tension test fixture

Tube only Tube with coupling

Tube only Tube with coupling

Tension test

- Fixture layout: The tension test fixture has a tube that is

bolted in solid on the right and it goes through a hub on the left that

can slide but not rotate. A threaded collar with a lever is screwed onto

the hub until it bottoms out against the end of the fixture. (See the threaded

collar and lever in the first photo)

- Application of load: When the lever is pushed down it moves

the hub to the left which pulls on the tube.

- Measurement method: Two collars are clamped to the tube 4 inches

apart. A dial indicator is mounted to one collar and the plunger rests

against the other. Two indicator assemblies are attached to the tube. One

is placed in the plain section of tube and the other is placed in the coupled

section of tube with a collar on each side of the coupling. The dial indicators

show the amount of stretch between the collars. A stiffer section of tube

will allow less stretch.

- Results: The collars in the plain tube stretched .005".

There was .001" stretch in the tube section with a coupling.

- Conclusion: This test demonstrates that in tension the tube

section with the coupling is stiffer than the plain tube.

Bend test fixture

Tube only Tube with coupling

Tube only Tube with coupling

Bend test

- Fixture layout: The bend test fixture has two tubes mounted

vertically. One tube has a coupling installed and the other does not. A

linkage connects the tubes at the top. A lever controlled eccentric mechanism

is located in the center of the linkage.

- Application of load: When the lever is moved the eccentric mechanism

shortens the linkage which pulls the tubes together causing them to bend.

The mechanism holds the tubes together once the lever has been flipped

for a more accurate reading.

- Measurement method: A collar with a 4 inch vertical arm is attached

to the tube. A dial indicator is mounted on top of the arm. The plunger

of the indicator rests against the tube. An identical assembly is installed

on each tube and they are positioned on the tube the same distance from

the fixture base. The indicators show how much bending takes place in the

4" section of each tube. A stiffer section of tube will allow less

bending.

- Results: The indicator in the plain section of tube bent .010".

There was .006" bend in the coupled tube.

- Conclusion: This test demonstrates that in bending the tube

section with the coupling is stiffer than the plain tube.

Framebuilder list |

Cases |

Packing |

Photos |

Reviews |

Comments |

Retailer list |

Installation |

Specifications |

Cost |

Retrofit or new? |

Travel adventures

Contact Information

S and S Machine's Home Page

Tube only Tube with coupling

Tube only Tube with coupling

Tube only Tube with coupling