Mercian Cycles

Builder Profile

|

Builder Statement: At Mercian Cycles, we’re renowned worldwide for quality custom cycle frames produced by experienced cycle frame builders. When you purchase a handbuilt cycle frame from our cycle shop in Derby, you can be sure you’ve bought into quality craftsmanship. |  |

|

Brief History Mercian Cycles began as a cycle shop in Derby in 1946. At Mercian we are proud of the history and traditional frame-building methods still used today. We keep frame records dating back to the 1970's which are often referred back to when owners want to trace the beginnings of their Mercian frame, as well as for subsequent frame orders for customers wanting exactly the same geometry and size that they have had before. The current "World Over" head and seat crest were introduced in the early / mid 1960's. Follow this link for a more complete history |

| Custom sizing Customers visiting our showroom to order a frame are sat upon a specially designed jig where skill, time and patience ensure a correct frame size and design - tailored to match the intended use of the cycle or frameset. The components to be used also play an important part of the frame order process, our framebuilders use the same model of component whilst building the frame to ensure that the finished frameset is built to suit you, your equipment and your cycling style. All of these minor details make sure that the complete cycle is the very best it can be. |

|

|

Large selection of frames and complete bikes always in stock at our Alvaston showroom |

|

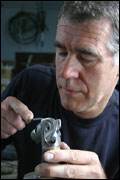

| Craftsmanship From the first stage of taking your order to the final clear lacquer paint finish - each member of the Mercian team is committed to service to you, as well as the production of a high quality product. We all have passion for the lightweight and sleek machines that Mercian Cycles produce and with over 200 years experience between the 9 team members - you can rely on their guidance, skill and expertise to produce the frame you really want. At Mercian's frame-building workshop there are no production lines. The method of building our frames has barely altered since the very beginning of Mercian Cycles. It really is a very traditional environment - looking back to the very best methods of hand-made quality. The frame order is passed to the framebuilder, who builds the frame from start to finish. With great skill and incredible patience he begins by preparing the lugs - drilling and filing, by hand, the cut-outs and intricate designs which make Mercian frames distinctive and beautiful. As Michael Kone (Bicycle Classics) was recently quoted, "That's the difference between buying craftsmanship and buying technology. Craftsmanship increases or at least maintains its value over the years, but technology gets severely devalued the minute it is sold, because everyone knows in a year it's going to be old news." |

|

|

Open Hearth Brazed: Mercian have brazed frames in an open hearth, since the 1940's, as we believe this reduces the possibility of overheating the tubing, unlike a welding torch which can be too harsh in the wrong hands. Open hearth brazing, in our experience, is much kinder to the lightweight metal tubes and also means that should a frame tube be damaged in use, we can undo the braze and replace a single tube meaning your frame gives you many years of pleasure. |

| The skill and artistry of the paint sprayer and the frame

finisher Patience is paramount. The frame is primed with etch coat primer, which is allowed to air dry in the clean conditions of the finishing room. Many of our 60+ colours are hand mixed from up to 8 colours to offer the deep and striking colours we have to choose from. The sprayer then coats the frame with layers of paint, before baking in a state-of-the art gas stoving oven to harden the surface at just the right temperature for a hard wearing and durable finish. Once the layers of paint for the main finish have been stoved, the frame is then masked off by hand, using low-tack masking tape, prior to the application of contrasting colour panels or bands, before baking once again after each layer of paint. The transfers are then positioned on the painted frame by another skilled craftsman. The transfers used are not "stickers", but traditional varnish-fix transfers, which may be more difficult to apply - but give a better finish, with no vinyl "step" at the edges of the transfer. This means that they are applied by adding a thin layer of transfer varnish to the area where the transfer is to be placed, once tacky, the transfer is then applied in position and the backing tissue paper carefully wiped off with water. The excess varnish is then removed with delicate solvents and wiped dry with a soft cloth. The transfers are then left to air dry for 48 hours to prevent crinkling or lifting during the varnish process. The lug-lining is added by hand with a small pen-like device, carefully filled with the selected colour and lug lines followed to pick-out the lugs and finish the frame beautifully. Contrast band or barber's pole edges are finished by hand with the finest paint brush. The transferred frame is given two coats of hard-wearing clear lacquer to protect the finished frame, before stoving in the oven once again. |

|

Recently renovated 1956 Mercian |

Frame Repairs and Renovation Service We can offer a repair and renovation service for all makes of cycle frame undertaken in our Derby workshop. Our experienced frame-builders and frame finishers use their expertise to repair and renovate all makes of steel cycle frames. Repairs, re-sprays and frame finishing are all completed in house using the best quality frame-building parts and highest quality stove enamels. Alloy frames also stove enameled. Repair and renovation includes: Preparation of the frame, existing paint removed sympathetically. Frames etch primed to give the best adhesion for the coats of paint. Frame inspection once primed for paint. Light sanding between coats of enamel to ensure a deep and glossy finish. A minimum of two coats of clear lacquer to protect the transfers and give a hard wearing durable finish. A final inspection before all the threads are cleaned and re-tapped to ready the frame for ease of building. If delivery is required - strong, durable packaging makes sure the frame reaches you in showroom condition. Period original Reynolds transfers are available, (see link below) as are many original older frame transfers for other frame manufacturers. If original transfers are not in our stock, we will try to source them for you if required. |

|

Shop Photos See some great photos of the Mercian shop and store here |

|

|

|

|

| S and S Couplings This coupling is in the process of being installed in a top tube. It is shown with a special nut, that is used only during brazing, which keeps the heat treated finish nut from being damaged by the heat. |

|

Mercian frame fitted with S and S Couplings Click for a larger image |

S&S Couplings S&S Stainless Steel Couplings are available for fitting on new frames. Supplied and fitted for £405 + VAT, which includes 2 S&S couplings, 1 coupling spanner and 1 set of cable splitters. |

Click for a larger image |

Mercian Cycles

7 Shardlow Rd

Alvaston, Derby DE24 0JG, UK

Telephone: (ENGLAND +44) 01332 752468

Fax: (ENGLAND +44) 01332 751033

e-mail: service@merciancycles.com